Casing nails are a type of fastener used in construction and woodworking, specifically designed to secure trim, baseboards, and other wooden elements to walls or structures. These nails are typically made of steel and have a smooth, rounded head, making them less visible once installed. The term casing refers to the process of covering or finishing the edges of a building or structure, and these nails play a crucial role in ensuring the stability and durability of such constructions. They are an essential component in the construction industry, providing a reliable and discreet method of fastening materials together.

What You'll Learn

- Nail Casing Basics: Understanding nail casing, its purpose, and types

- Installation Techniques: Methods for driving nails into casing efficiently

- Materials and Tools: Materials and tools required for casing nail work

- Safety Precautions: Essential safety measures to prevent injuries during casing nail tasks

- Common Issues: Troubleshooting common problems when casing nails

Nail Casing Basics: Understanding nail casing, its purpose, and types

Nail casing is a fundamental concept in carpentry and construction, referring to the process of encasing or surrounding a nail with a specific material or technique. This practice is essential for enhancing the structural integrity and aesthetics of wooden structures. The primary purpose of nail casing is to provide a protective barrier around the nail, ensuring that it holds its position securely and preventing any potential damage to the surrounding wood. This technique is particularly crucial when joining two pieces of wood together, as it helps to create a strong and durable bond.

There are several methods and materials used for nail casing, each offering unique benefits. One common approach is to use a piece of wood called a 'casement' or 'casement strip,' which is typically made of the same type of wood as the project. This casement is placed around the nail, often with a small gap to allow for the nail's head. The casement can be glued, nailed, or even wrapped around the nail, providing a neat and secure finish. This method is especially useful for visible joints, such as those in furniture or trim, where a clean and refined appearance is desired.

Another type of nail casing involves the use of metal or plastic casings. These casings are often used in construction projects where strength and durability are essential. Metal casings, for instance, can be made of brass or steel and are commonly used in exterior applications due to their resistance to corrosion. Plastic casings, on the other hand, are lightweight and offer a cost-effective solution for various carpentry projects. These casings can be easily cut to size and provide a protective barrier without adding significant weight to the structure.

In addition to the materials, the technique of nail casing also varies. Some carpenters prefer to use a 'casement nail,' which is a specialized nail designed for this purpose. These nails often have a flat or rounded head, allowing them to be driven into the wood without protruding excessively. By using the right type of nail and ensuring proper casing, the joint becomes nearly invisible, creating a seamless and professional finish.

Understanding nail casing is essential for any carpenter or DIY enthusiast, as it contributes to the overall quality and longevity of wooden structures. Whether using traditional casement strips or modern casings made of metal or plastic, the goal remains the same: to provide a protective barrier that strengthens the bond between wooden elements. With the right techniques and materials, nail casing can elevate the craftsmanship of any woodworking project.

Understanding the Meaning of a Bruised Toe Nail

You may want to see also

Installation Techniques: Methods for driving nails into casing efficiently

The term "casing nail" typically refers to a specific type of nail used in construction, particularly in the context of framing and sheathing. These nails are designed to secure wood components together, often in applications where structural integrity and precision are crucial. When discussing installation techniques for casing nails, it's important to consider the various methods that can be employed to drive these nails efficiently and effectively.

One common technique is the use of a nail gun, which is a specialized tool designed for driving nails into wood. Nail guns come in different types, such as manual or power-driven models. Manual nail guns require the installer to manually load and drive the nail, offering a more controlled and precise approach. Power nail guns, on the other hand, are typically battery-operated or plugged into a power source, providing faster and more efficient nailing, especially for large-scale projects. When using a nail gun, it is crucial to select the appropriate nail size and type for the specific application. Casing nails often come in various lengths and diameters to accommodate different framing needs.

Another traditional method for driving casing nails is by hand using a hammer. This technique requires skill and precision to ensure the nail is driven straight and at the correct depth. The installer must carefully position the nail, typically at a slight angle, and then strike it with the hammer. This method is more time-consuming but can be useful for smaller projects or when access to power tools is limited. It is essential to use the right type of hammer for the job, with a curved or ball peen head being ideal for driving casing nails into wood.

For efficient installation, it is recommended to use a technique called "driving for clearance." This involves positioning the nail slightly above the surface of the wood and then driving it down until it is flush with the wood. This method ensures that the nail head is level with the surface, providing a clean and professional finish. Additionally, using a nail set or a nail guide can help achieve consistent and accurate nail placement.

In some cases, installing casing nails may require the use of specific accessories. For example, nail plates or nail guides can be used to provide support and stability when driving nails into the casing. These accessories help prevent the nail from splitting the wood and ensure a secure hold. Furthermore, when working with larger casing nails, a nail puller or a nail extractor might be necessary to remove any misdriven or damaged nails.

Mastering the art of driving casing nails efficiently involves a combination of the right tools, techniques, and accessories. Whether using nail guns or traditional hammers, understanding the specific requirements of the project and selecting the appropriate nail type and size is essential. With practice and attention to detail, installers can ensure a professional and secure finish for their casing nail installations.

Mastering the Art of End Nailing: A Guide to Precision

You may want to see also

Materials and Tools: Materials and tools required for casing nail work

To begin with, let's clarify the term "casing nail." Casing nails are a type of finishing nail used in carpentry and construction to secure trim or casing to a wall or surface. These nails are typically thin, sharp, and designed to leave a minimal impression in the wood, ensuring a clean and professional finish. The term "casing" refers to the decorative trim or molding that is attached to the exterior or interior walls of a building, often made from materials like wood, vinyl, or fiber cement.

Now, when it comes to casing nail work, having the right materials and tools is essential for a successful and efficient project. Here's a detailed breakdown of the materials and tools you'll need:

Materials:

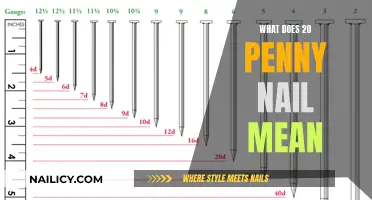

- Nails: The primary material is casing nails, which come in various sizes depending on the application. Common sizes include 18-gauge and 16-gauge nails, with lengths ranging from 1-1/2 inches to 2-1/2 inches. Fine-tipped casing nails are preferred for their ability to leave a small, almost invisible, hole in the wood.

- Trim or Casing: This is the decorative element you intend to attach to the wall. It can be made from various materials such as wood (e.g., pine, oak), vinyl, fiber cement, or even aluminum. Ensure that the trim is cut to the desired length and shape for your project.

- Adhesive: Construction-grade glue or a wood adhesive can be used to provide additional strength and hold the trim in place. Choose a glue that is compatible with the materials you are working with.

- Wood Filler: If there are any holes or imperfections in the wall or trim, wood filler can be used to fill them before nailing. This ensures a smooth surface and a professional finish.

- Paint or Finish: Depending on your project's requirements, you might want to apply paint, stain, or a protective finish to the trim after nailing it in place.

Tools:

- Hammer: A standard hammer is essential for driving casing nails. Opt for a curved claw hammer, which is designed for precision work and provides a better grip for smaller nails.

- Nail Set: A nail set, also known as a nail-setting punch, is a useful tool for driving casing nails without leaving a visible mark. It helps to set the nail at a precise angle, ensuring a clean finish.

- Tape Measure: Accurate measurements are crucial for casing nail work. A tape measure will help you determine the correct lengths of trim and ensure that the casing is straight and level.

- Spirit Level: This tool is used to ensure that the trim is installed vertically and horizontally straight, creating a professional appearance.

- Pencil and Marking Tools: You'll need a pencil and a marking gauge or a marking knife to make precise marks on the wood for nail placement.

- Power Drill (Optional): For larger projects or when driving multiple nails, a power drill with a nail starter bit can speed up the process.

- Safety Gear: Don't forget personal protective equipment, including safety glasses, gloves, and a dust mask to ensure a safe working environment.

Having the right materials and tools will make your casing nail work more efficient and the final result more aesthetically pleasing. It's always a good idea to prepare and gather your supplies before starting any construction or carpentry project.

Unveiling the Mystery: Why Men Paint Their Nails Black

You may want to see also

Safety Precautions: Essential safety measures to prevent injuries during casing nail tasks

Before we delve into the safety precautions, it's important to understand what 'casing nail' entails. Casing nails are a specific type of fastening technique used in construction and woodworking, where nails are driven into the wood to secure various materials together. This process can be done by hand or with power tools, and it requires precision and care to avoid accidents. The term 'casing' refers to the act of installing or fastening materials, often in a circular or cylindrical pattern, to create a secure and durable bond.

Now, let's explore the essential safety measures that should be followed to ensure a safe working environment when performing casing nail tasks:

Personal Protective Equipment (PPE): Wearing appropriate PPE is fundamental to safety. Safety goggles are a must to protect your eyes from any potential debris or flying fragments. Additionally, consider wearing a dust mask to avoid inhaling wood dust, especially when working with power tools. Gloves can provide a better grip and protect your hands from blisters and cuts, but ensure they are made of a breathable material to prevent overheating.

Tool Safety: When using power tools for casing nails, it is crucial to follow the manufacturer's guidelines. Always switch off the tool when not in use and disconnect the power source. Keep the work area clear of any obstacles or trip hazards. Ensure the tool's blades or tips are sharp and in good condition to prevent slipping and potential injuries. For manual casing nail tasks, using the correct nail size and type is essential. Avoid over-driving nails, as this can lead to wood splitting and potential kickback, especially with power tools.

Work Area Organization: A well-organized work area is key to safety. Keep your workspace clean and free of clutter to reduce the risk of accidents. Ensure proper lighting to avoid eye strain and potential hazards in dark areas. Use non-slip mats or wear shoes with good grip to prevent slips and falls. When working with multiple materials, clearly label and separate them to avoid confusion and potential injuries.

Ventilation and Respiratory Safety: Woodworking often involves dust and fumes, which can be harmful if inhaled. Ensure proper ventilation in the work area to minimize the concentration of airborne particles. Consider using a dust collection system when possible. If working in enclosed spaces, take regular breaks to breathe fresh air and stay hydrated.

Training and Awareness: Proper training is essential, especially when using power tools. Familiarize yourself with the equipment and its safe operating procedures. Stay aware of your surroundings and be cautious when handling tools or materials. Regularly inspect your tools for any signs of damage or wear and replace them as necessary.

By implementing these safety precautions, you can significantly reduce the risk of injuries and create a safer working environment for yourself and those around you. Remember, safety should always be a top priority in any construction or woodworking project.

Unraveling the Mystery: What Does a Blue Cast Under Your Nails Indicate?

You may want to see also

Common Issues: Troubleshooting common problems when casing nails

Casing nails are an essential component in construction and woodworking, providing a protective layer around the nail head and preventing it from being visible once the nail is driven into the material. However, like any fastening system, casing nails can encounter issues that may compromise their functionality or appearance. Here are some common problems and troubleshooting tips to ensure you can address them effectively:

- Misaligned Casing: One of the most frequent issues is misaligned casing, where the nail head protrudes above or below the surface of the material. This can happen due to improper nail placement or a lack of precision when driving the nail. To fix this, carefully inspect the nail's position before driving it. Ensure the nail is straight and aligned with the desired casing depth. Adjust the nail's angle and position if necessary, and use a nail set or a similar tool to guide the nail into the correct position.

- Uneven Casing Depth: Another common problem is uneven casing depth, resulting in a visible nail head or a gap between the casing and the material's surface. This issue often arises from inconsistent nail driving techniques. To troubleshoot, maintain a steady and controlled force when driving the nail. Use a nail set or a mallet to ensure a consistent impact, helping to achieve an even casing depth. Practice precision and patience to master this technique.

- Casing Pop-Out: Over time, casing nails can loosen and cause the casing to pop out of the material. This is often due to the nail's inability to hold the casing securely in place. To prevent this, consider using a nail with a larger head or a nail that is specifically designed for casing. Additionally, ensure that the nail is driven deep enough to provide adequate support. Applying a small amount of construction adhesive around the nail can also improve its holding power.

- Rust and Corrosion: Outdoor projects or those involving moisture can lead to rust and corrosion on casing nails. This not only affects the nail's appearance but also its structural integrity. To address this, choose casing nails made from rust-resistant materials like stainless steel or galvanized steel. Regularly inspect and clean the nails, especially in areas prone to moisture. Applying a protective coating or primer can also help prevent corrosion and maintain the nail's longevity.

Troubleshooting common issues with casing nails requires attention to detail and a methodical approach. By understanding the causes of these problems, you can implement the appropriate solutions to ensure a successful and professional finish to your projects. Remember, practice and precision are key to mastering the art of casing nail installation.

Curled Finger Nails: Unraveling the Mystery

You may want to see also

Frequently asked questions

Casing nails are a type of fastener specifically designed for securing casing or protective tubes around electrical wires, cables, or plumbing lines. They provide a secure and discreet way to hold the casing in place, ensuring the wires or cables are safely enclosed and protected from damage or exposure.

Casing nails are typically smaller and thinner than standard nails, with a flat or slightly curved head. They are often made of steel or brass and have a sharp point to easily penetrate the casing material. The design allows for a tight grip and secure hold without causing visible damage to the casing.

These nails are commonly used with materials like plastic, PVC, metal, or composite casing. They are ideal for securing electrical boxes, conduit fittings, or any application where a discreet and reliable fastening method is required.

Yes, casing nails can be reused multiple times. They are designed to be driven into the casing material and then easily removed without damaging the casing. This reusability makes them a cost-effective solution for various construction and maintenance projects.

Absolutely! Casing nails are versatile and can be used both indoors and outdoors. They are resistant to corrosion and weather damage, making them suitable for outdoor applications, such as securing electrical wiring in outdoor fixtures or enclosing plumbing lines in outdoor structures.