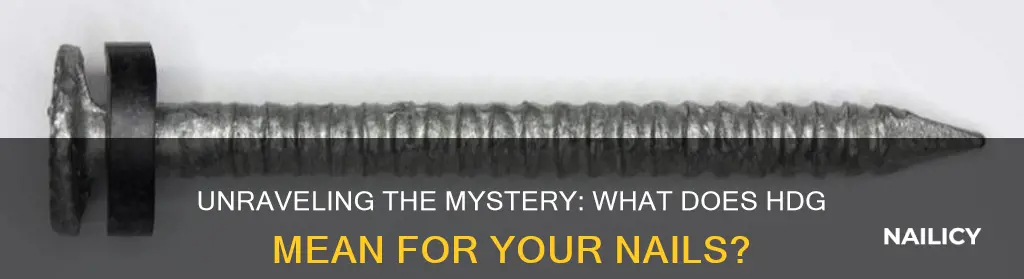

HDG, or High-Density Galvanized, is a type of nail material that offers superior strength and durability for various nail-driving applications. This innovative nail type is designed to provide enhanced resistance to corrosion, making it ideal for outdoor construction projects and environments exposed to moisture. The unique composition of HDG nails ensures they are less prone to rusting, thus maintaining their structural integrity over time. This makes HDG nails a popular choice for professionals in the construction industry, as they offer a reliable and long-lasting solution for securing materials.

What You'll Learn

- HDG: Heat-treated, deep-drawn, and galvanized steel for nail manufacturing

- Nail Strength: HDG nails offer superior tensile strength and durability

- Corrosion Resistance: HDG nails resist rust and corrosion in harsh environments

- Versatility: Suitable for various construction and woodworking applications

- Cost-Effective: HDG nails provide long-term savings due to their durability

HDG: Heat-treated, deep-drawn, and galvanized steel for nail manufacturing

The term "HDG" in the context of nail manufacturing refers to a specific process that combines heat treatment, deep drawing, and galvanizing to produce high-quality steel nails. This process is an advanced manufacturing technique that ensures the nails are strong, durable, and resistant to corrosion.

Heat treatment is the initial step in the HDG process. It involves heating the steel to a precise temperature and then rapidly cooling it. This treatment hardens the steel, making it more robust and less prone to wear and tear. The heat treatment process is crucial as it enhances the nail's structural integrity, ensuring it can withstand various environmental conditions.

Deep drawing is the next phase, where the heated steel is shaped into the desired nail form. This process requires precision and specialized equipment to create the specific nail profiles, such as smooth, rounded, or pointed tips. Deep drawing ensures that the nails have a consistent and professional finish, making them suitable for various construction and woodworking applications.

Galvanizing is the final step in the HDG process. It involves immersing the steel nails in a molten zinc bath, creating a protective zinc coating. This coating provides excellent corrosion resistance, making the nails ideal for outdoor use and applications where moisture is present. The galvanizing process significantly extends the lifespan of the nails, ensuring they remain strong and functional over an extended period.

By combining heat treatment, deep drawing, and galvanizing, HDG steel nails offer superior performance and longevity. This manufacturing process ensures that the nails are not only strong but also highly resistant to environmental factors, making them a reliable choice for professionals in the construction and woodworking industries. The HDG process is a testament to the advancement of nail manufacturing techniques, providing a product that meets the demands of modern building and crafting needs.

Nail Care Secrets: Unlocking the Meaning of Improved Nails

You may want to see also

Nail Strength: HDG nails offer superior tensile strength and durability

HDG nails, or Hot-Dip Galvanized nails, are an excellent choice for anyone seeking to enhance the strength and longevity of their nail projects. These nails are crafted from carbon steel and then subjected to a hot-dip galvanizing process, which involves immersing the nails in a molten zinc bath. This process creates a strong bond between the zinc and the steel, resulting in a protective layer that shields the nails from corrosion and rust. The galvanization process significantly increases the nail's tensile strength, making HDG nails a reliable and robust option for various construction and woodworking applications.

The superior tensile strength of HDG nails is a result of the zinc coating's ability to form a protective barrier. This barrier prevents oxygen and moisture from reaching the underlying steel, thus inhibiting rust formation. As a consequence, HDG nails exhibit exceptional resistance to wear and tear, ensuring that your projects remain sturdy and reliable over an extended period. Whether you're working on outdoor structures, roofing projects, or any application where nail strength is critical, HDG nails provide the necessary durability to withstand the test of time.

In addition to their strength, HDG nails also offer excellent flexibility, allowing them to bend and adjust to various surfaces without breaking. This flexibility is particularly useful when dealing with uneven or irregular substrates, ensuring a secure hold without compromising the nail's integrity. The combination of strength and flexibility makes HDG nails an ideal choice for professionals and DIY enthusiasts alike, providing a reliable solution for a wide range of projects.

Furthermore, the hot-dip galvanizing process ensures that HDG nails have a consistent and uniform coating, promoting even distribution of the protective zinc layer. This uniformity contributes to the nails' overall performance, ensuring that each nail provides the same level of strength and protection. The consistency of HDG nails makes them a reliable choice for large-scale projects, where uniformity is essential to maintain the structural integrity of the entire assembly.

In summary, HDG nails are an exceptional choice for anyone seeking to enhance the strength and durability of their nail projects. With their superior tensile strength, resistance to corrosion, and flexibility, these nails offer a reliable and robust solution for various construction and woodworking applications. By choosing HDG nails, you can ensure that your projects will stand the test of time, providing a solid and secure foundation for your endeavors.

White Spot Under Nail: What It Could Mean

You may want to see also

Corrosion Resistance: HDG nails resist rust and corrosion in harsh environments

HDG nails, or Hot-Dip Galvanized nails, are an excellent choice for construction and woodworking projects that require enhanced durability and longevity, especially in outdoor or harsh environments. The process of hot-dip galvanizing involves immersing steel nails in a molten zinc bath at a temperature of around 860°F (460°C). This process creates a strong bond between the zinc and the steel, forming a protective layer that shields the nail from the elements.

The primary benefit of HDG nails is their exceptional corrosion resistance. Zinc, being a highly reactive metal, forms a protective oxide layer on the surface when exposed to air. This layer, known as the 'zinc patina,' acts as a barrier, preventing oxygen and moisture from reaching the underlying steel and causing rust. As a result, HDG nails are highly resistant to rust and corrosion, making them ideal for outdoor applications, such as landscaping, fencing, and decking, where nails are exposed to rain, humidity, and varying temperatures.

In harsh environments, where moisture and salt are prevalent, HDG nails excel. The zinc coating provides a protective shield, preventing the steel from coming into direct contact with these corrosive elements. This is particularly important in coastal areas or regions with high humidity, where traditional steel nails may quickly deteriorate due to the constant exposure to moisture and salt.

The corrosion resistance of HDG nails is not just limited to outdoor applications. They are also valuable in indoor environments where moisture and humidity levels can vary. For example, in construction projects, HDG nails can be used to secure wood framing, ensuring that the nails remain rust-free even after prolonged exposure to indoor moisture, such as during the curing process of concrete.

Furthermore, the hot-dip galvanizing process ensures that the nails have a consistent and uniform zinc coating, providing comprehensive protection against corrosion. This process also results in a smooth, aesthetically pleasing surface, making HDG nails suitable for both functional and decorative applications. Whether used in landscaping, construction, or woodworking, HDG nails offer a reliable and long-lasting solution, ensuring that your projects remain sturdy and attractive over time.

Unraveling the Mystery: What Does One Blue Nail Symbolize?

You may want to see also

Versatility: Suitable for various construction and woodworking applications

HDG nails, or Hot-Dip Galvanized nails, are an essential tool in any construction or woodworking project, offering a versatile and reliable solution for fastening materials. The process of hot-dip galvanizing involves submerging steel nails in a molten zinc bath, creating a protective layer that enhances their durability and resistance to corrosion. This treatment makes HDG nails highly suitable for a wide range of applications, ensuring long-lasting performance in demanding environments.

In construction, these nails are invaluable for securing various building materials. From framing structures to roofing and siding, HDG nails provide the necessary strength and stability. Their ability to withstand harsh weather conditions and resist rusting makes them ideal for outdoor projects, ensuring that buildings remain sturdy and aesthetically pleasing over time. For instance, when constructing a wooden fence, HDG nails can be used to attach posts, ensuring a secure and long-lasting barrier.

Woodworking enthusiasts will also find HDG nails to be a versatile choice. Whether crafting furniture, building cabinets, or creating intricate wooden designs, these nails offer a reliable fastening method. The galvanized coating prevents wood rot and decay, making it perfect for projects that require exposure to moisture or outdoor conditions. Additionally, the nails' strength and sharpness ensure clean, precise holes, allowing for a professional finish.

The versatility of HDG nails extends to various other applications. They are commonly used in landscaping for securing wooden fences, trellises, and garden structures. In marine environments, where corrosion resistance is crucial, HDG nails provide an ideal solution for fastening materials together. Moreover, their strength and reliability make them suitable for heavy-duty projects, such as securing scaffolding or building temporary structures.

In summary, HDG nails are a versatile and indispensable tool for any construction or woodworking endeavor. Their hot-dip galvanized coating ensures durability and corrosion resistance, making them perfect for a wide range of applications. From construction sites to woodworking workshops, these nails offer a reliable fastening solution, ensuring projects are completed efficiently and with long-lasting results. With their ability to withstand various conditions, HDG nails are a wise investment for professionals and DIY enthusiasts alike.

Yellowish Big Toe Nails: Understanding the Possible Causes and When to Seek Help

You may want to see also

Cost-Effective: HDG nails provide long-term savings due to their durability

HDG nails, or Hot-Dip Galvanized nails, are an excellent choice for those seeking a cost-effective and durable fastening solution. The process of creating HDG nails involves dipping steel nails into a molten zinc bath, resulting in a thick layer of zinc coating. This coating not only enhances the nail's strength but also provides a protective barrier against corrosion, ensuring a longer lifespan.

One of the key advantages of HDG nails is their resistance to rust and corrosion. Unlike standard nails, which can quickly deteriorate when exposed to moisture and harsh weather conditions, HDG nails remain robust and reliable over time. This durability is particularly beneficial in outdoor construction projects, landscaping, or any application where nails are subject to the elements. By investing in HDG nails, you can significantly reduce the need for frequent replacements, thus saving money in the long run.

The cost-effectiveness of HDG nails is evident in their ability to withstand the test of time. While initial costs might be slightly higher compared to standard nails, the long-term savings are substantial. HDG nails' durability means they require fewer replacements, reducing labor costs associated with frequent nail changes. Additionally, their resistance to corrosion eliminates the need for additional maintenance, such as regular painting or treating, which can be both time-consuming and expensive.

In construction and building projects, HDG nails offer a practical and economical solution. Their strength and resistance to corrosion make them ideal for securing various materials, from wood and metal to concrete. By using HDG nails, contractors and DIY enthusiasts can ensure a secure and long-lasting bond without compromising on quality. This not only saves money but also ensures a professional finish, as the nails provide a reliable and consistent hold.

Furthermore, the versatility of HDG nails allows for their use in a wide range of applications. From residential projects to industrial settings, these nails can be employed in various construction techniques. Whether it's framing, roofing, or securing outdoor structures, HDG nails provide a cost-effective and reliable solution, ensuring that your investment in nails translates to long-term savings and a job well done.

Unraveling the Mystery: What Causes Bruises Under Your Nails?

You may want to see also

Frequently asked questions

HDG typically refers to "High-Definition Gel" or "High-Definition Gel Polish," which is a type of nail enhancement product. It is a gel-based formula that provides a long-lasting, chip-resistant finish to the nails, offering a high-definition look and feel.

Applying HDG involves a process similar to traditional nail polish. First, the natural nail is prepared by filing and shaping. Then, a base coat is applied to protect the nail and provide an even surface. After that, the HDG color of choice is painted onto the nail, and a top coat is added to seal and protect the color. The process may require curing under a UV or LED lamp, depending on the brand.

HDG offers several advantages over traditional nail polish. It provides a longer-lasting manicure, often lasting up to two weeks without chipping. The high-definition formula ensures a smooth and glossy finish, enhancing the overall appearance of the nails. Additionally, HDG is known for its durability, resistance to peeling, and ability to maintain its vibrant color for an extended period.

Yes, one of the key benefits of HDG is its ease of removal. Unlike regular gel nails, HDG can be gently lifted off the nail surface using a nail polish remover. This process is less damaging to the natural nail compared to traditional gel manicures, making it a popular choice for those seeking a healthier nail care routine.