Nail guns are powerful tools used in construction and woodworking, and understanding the degrees on a nail gun is crucial for safe and effective use. The degrees on a nail gun refer to the angle at which the nail is driven into the material. This angle is important because it determines the strength and stability of the nail's hold. Different degrees offer various benefits, such as providing a steeper angle for heavy-duty applications or a shallower angle for more delicate work. Knowing how to adjust these degrees can significantly impact the quality of your projects, ensuring that nails are driven straight and securely.

| Characteristics | Values |

|---|---|

| Degree Type | Angle of Fire, Degree of Angle |

| Purpose | Adjusts the angle at which the nail is fired, allowing for precise placement and control |

| Impact | Influences the nail's penetration and the material it can be used on |

| Common Values | 18, 20, 22, 24, 30, 36, 45, 50 degrees |

| Benefits | Improved accuracy, reduced damage to workpiece, versatility for different projects |

| Considerations | Higher degrees offer more flexibility but may require more skill; lower degrees are better for delicate work |

| Safety | Proper degree selection is crucial for safety, as it affects the nail's trajectory and potential injury risk |

What You'll Learn

Nail Gun Degrees: Angle and force settings explained

The degrees on a nail gun refer to the angle of the nail gun's firing mechanism, which is a crucial setting for achieving the desired nail placement and driving force. This angle is typically measured in degrees and allows users to adjust the nail gun's trajectory and impact. Understanding and utilizing these degrees effectively can significantly impact the quality of your work, especially in construction and woodworking projects.

When you see the term "degrees" on a nail gun, it often pertains to the angle of the nail gun's trigger or the angle at which the nail is driven into the workpiece. This angle is adjustable, allowing users to customize the nail gun's behavior for different materials and applications. For example, a higher degree setting might result in a more aggressive nail-driving action, suitable for dense materials like hardwood, while a lower degree setting could provide a gentler approach, ideal for thinner materials or delicate projects.

The force setting, often associated with the degrees, determines the power and impact of the nail gun's firing. It controls the amount of energy transferred to the nail, influencing the nail's penetration depth and the overall driving force. Higher force settings are beneficial for heavy-duty applications, ensuring the nail is firmly secured, while lower force settings are more precise and can be used for intricate work or when working with softer materials.

Adjusting the nail gun's degrees and force settings is a skill that becomes second nature with practice. It requires a keen eye and a feel for the material being worked with. For instance, when driving nails into a piece of wood, you might need to increase the degrees and force to penetrate the denser wood, ensuring a secure hold. Conversely, for lightweight materials like foam or thin plywood, a lower degree setting and reduced force might be sufficient.

Mastering the art of nail gun degrees and force settings opens up a world of possibilities for precise and efficient nailing. It allows professionals and DIY enthusiasts alike to tackle a wide range of projects with confidence. By understanding the relationship between these settings and the material, you can achieve professional-grade results, ensuring that your nails are driven accurately and securely, every time.

Unraveling the Mystery: What Bent Nails Symbolize

You may want to see also

Degree Impact: How nail gun degrees affect nail driving

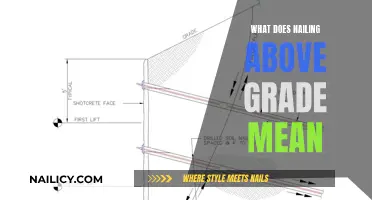

The degrees on a nail gun are a crucial aspect of its functionality, especially when it comes to driving nails into various materials. These degrees refer to the angle at which the nail is fired from the gun, and they play a significant role in the impact and penetration of the nail. Understanding the impact of these degrees is essential for anyone using a nail gun, as it can affect the quality of the work and the overall performance of the tool.

When you adjust the degree settings on a nail gun, you are essentially controlling the trajectory and force of the nail. Higher degree settings result in a more vertical angle, causing the nail to drive straight into the material with increased force. This is particularly useful when working with dense or hard materials where a steeper angle can provide better holding power. For example, when framing a house, a higher degree setting might be preferred to ensure the nails firmly hold the wooden studs together.

On the other hand, lower degree settings offer a more oblique angle, allowing the nail to enter the material at a gentler slope. This is advantageous when working with softer materials or when you need to avoid splitting or damaging the surface. Lower degrees are also beneficial for trim work, where precision and control are essential to achieving a clean and professional finish. By adjusting the degrees, you can customize the nail gun's performance to suit the specific requirements of each project.

The impact of these degrees is also related to the nail's exit velocity and the overall energy transferred to the material. Higher degrees can provide a more powerful impact, which is beneficial for heavy-duty applications. However, it's important to note that excessive force might lead to nail bending or even breaking, especially with lower-quality nails. Finding the right balance between degree settings and nail type is crucial for optimal results.

In summary, the degrees on a nail gun are not just random markings but a critical feature that influences nail driving. By understanding the impact of these degrees, users can adjust the settings to match the material and project requirements. Whether it's for construction, woodworking, or any other application, mastering the degree settings will undoubtedly enhance the efficiency and precision of your nail-driving tasks.

Uncover the Mystery: What Do Bluish Nails Indicate?

You may want to see also

Degree Adjustment: Methods to adjust nail gun degrees

The degree adjustment on a nail gun is a crucial feature that allows users to customize the angle of the nail gun's firing mechanism, which is particularly useful for various construction and woodworking tasks. This adjustment is often represented by a dial or a set of screws, and understanding how to use it effectively can significantly improve your work efficiency and the quality of your projects.

When you hear the term 'degrees' in the context of a nail gun, it refers to the angle at which the nail is driven into the material. This angle is measured in degrees, typically ranging from 15 to 180 degrees, depending on the specific nail gun model. Adjusting this angle is essential for achieving the desired nail placement and ensuring the nail gun's functionality in different applications. For example, a lower degree setting is ideal for driving nails into softer materials like wood, while a higher degree is more suitable for harder materials or when you need a more precise angle.

To adjust the degree setting, locate the degree adjustment mechanism on your nail gun. This could be a small dial, a set of screws, or a lever, often located near the trigger or the nail magazine. Turn or adjust this mechanism in a clockwise or counterclockwise direction to increase or decrease the degree angle. The direction of adjustment depends on the specific design of your nail gun, so it's essential to consult the user manual for guidance.

For most nail guns, a higher degree setting will result in a more vertical nail drive, while a lower degree will provide a more angled or inclined nail placement. This adjustment is particularly useful when working with various materials and structures, allowing you to drive nails at different angles without compromising the nail gun's performance. It's important to note that the degree adjustment should be made gradually, and you should test the nail gun at each setting to ensure the desired angle is achieved.

Additionally, some nail guns offer a fine-tuning feature for the degree adjustment, allowing for even more precise control. This feature might be a small knob or a secondary dial that provides a more granular adjustment. Fine-tuning the degree setting can be beneficial when you need to make minor adjustments or when working with specific project requirements. Always refer to the manufacturer's instructions for the exact method of fine-tuning, as this feature may vary between different nail gun models.

Unraveling the Mystery: What Do Nail Gauges Really Mean?

You may want to see also

Degree Safety: Safety considerations for different nail gun degrees

The term "degrees" on a nail gun refers to the angle at which the nail is driven into the material. This angle is crucial as it determines the force and depth of the nail's insertion, impacting the overall quality and security of the fastening. Different nail guns offer various degree settings, allowing users to adjust the angle to suit specific tasks and materials. Understanding these degree settings and their implications is essential for ensuring safety and achieving optimal results.

For general construction and woodworking, a common degree setting is 15 to 20 degrees. This angle provides a balance between speed and strength, allowing for quick and efficient fastening without compromising the nail's holding power. When using this setting, it's important to maintain a steady hand and a firm grip on the nail gun to prevent the nail from protruding too far or causing damage to the surrounding material.

In contrast, finer degree settings, such as 10 or 15 degrees, are ideal for delicate work, like trim carpentry or installing trim and molding. These lower angles ensure a more precise and controlled insertion, reducing the risk of splitting the wood or damaging the surface. However, this precision comes at the cost of a slower application process, requiring more careful handling to avoid errors.

On the other end of the spectrum, higher degree settings, typically above 25 degrees, are used for heavy-duty applications like roofing or structural work. These angles provide a more aggressive nail insertion, allowing for faster and stronger fastenings. While this setting is powerful, it also requires increased caution to prevent the nail from bending or breaking, especially when working with thicker materials.

When adjusting the degree setting, it's crucial to consider the type of material and the desired outcome. Different degrees offer varying levels of control and speed, and selecting the appropriate setting can significantly impact the project's success and the user's safety. Always refer to the manufacturer's guidelines for specific recommendations and safety instructions related to your nail gun's degree settings.

Decoding Nail Drill Bit Colors: What They Mean

You may want to see also

Degree Maintenance: Maintaining nail gun performance at various degrees

The degrees on a nail gun refer to the angle at which the nail gun's trigger is set, and this setting is crucial for achieving the desired nail placement and driving force. Maintaining the correct degree setting is essential for optimal performance and to ensure the nail gun operates efficiently across various projects. Here's a guide to understanding and maintaining nail gun performance at different degrees:

Understanding the Degrees:

The degree setting on a nail gun is typically adjusted using a dial or knob, often located near the trigger. This adjustment allows users to select the desired angle, which is measured in degrees. Common settings range from 0 to 180 degrees, with each degree representing a small increment of angle. The higher the degree setting, the more force is applied to the nail, and the more the nail gun's trigger is pulled back.

Impact on Performance:

- Nail Placement: Different projects require specific nail placement. For example, when fastening trim or baseboards, a lower degree setting (around 10-20 degrees) ensures a precise and controlled nail drive, minimizing the risk of splitting the wood. In contrast, higher degree settings (50-90 degrees) are ideal for driving longer nails into sturdy materials like studs or joists.

- Driving Force: The degree setting directly influences the force with which the nail is driven. Higher degrees provide more power, which is beneficial for heavy-duty applications. However, excessive force can lead to nail misalignment or damage to the workpiece.

Maintaining Optimal Performance:

- Regular Adjustment: It is recommended to adjust the degree setting for each project to ensure the best results. Start with a standard setting and fine-tune as needed. For example, when working with delicate materials like plywood, a lower degree setting might be more appropriate.

- Practice and Experience: Users should become familiar with the nail gun's performance at various degrees through practice. This will help in quickly identifying the right setting for different tasks, improving efficiency on the job site.

- Tool Maintenance: Regular maintenance of the nail gun is essential. Keep the trigger mechanism clean and lubricated to ensure smooth operation at any degree setting. Check for any wear and tear, especially after extended use, and replace parts if necessary.

Safety Considerations:

When adjusting the degree setting, always prioritize safety. Ensure the nail gun is unplugged or the power is disconnected to prevent accidental firing. Additionally, wear appropriate safety gear, including eye and ear protection, to safeguard against any potential debris or noise.

By understanding the significance of the degrees on a nail gun and implementing proper maintenance practices, users can ensure consistent performance and achieve professional-quality results in various construction and woodworking projects.

Unraveling the Mystery: Pinkie Nail Length and Its Significance

You may want to see also

Frequently asked questions

The degrees on a nail gun typically indicate the angle of the nail-driving mechanism. This angle is crucial as it determines the direction and force with which the nail is driven into the workpiece. Different degrees offer various benefits, such as precision in specific applications or the ability to drive nails at different angles.

The choice of degree depends on the type of project and the desired outcome. For example, a 18-degree angle is common for general-purpose nailing, offering a balance between speed and accuracy. A 22-degree angle is often used for trim work, providing a more precise entry point. For projects requiring a nail to be driven at a specific angle, like roofing, a 30-degree angle might be preferred.

It's generally not recommended to use a nail gun with a degree setting that's not specified in the manufacturer's instructions. Different nail guns have varying optimal angle settings, and using an incorrect angle can lead to poor nail placement, reduced holding power, or even damage to the tool. Always refer to the manual for the recommended degree settings.

The 'degrees of freedom' refer to the independent movements a nail gun can offer. A higher degree of freedom allows for more adjustable settings, such as angle, depth of drive, and even the ability to adjust the nail's position in the magazine. This feature enhances the tool's versatility and user control, making it suitable for a wide range of applications.

Adjusting the degree setting varies depending on the nail gun model. Some tools may have a simple dial or knob, while others might require a more complex process involving removing a cover or adjusting a screw. Always consult the user manual for specific instructions on how to adjust the degree setting safely and effectively.